Eidoll sales the microreesistor type current fuse ,all the specification as bellow:

Ň»�ˇ˘

2T 3*8 microresistor type current fuse

Specification

1.MODEL NUMBER AND

SAFETY CERTIFICATION

1-1 Model Number: Part

Number+Rated Current+Rated Voltage+Approvals.

example:

2T 1.2

250V 1)Part

Number

2) Rated Current

1Ł©

2Ł©

3Ł©

3) Rated Voltage

1-2Rated Current And Voltage

Rated Current: 32 mA~1

Rated Voltage:125V/250V/400 AC

1-3Marking

The fuse shall have the following marking:

Specification:Characteristic Symbol+Rated Voltage

32mA~800mA : _mA 1A~1:_A

Trade mark:The ManufactureˇŻs Logo+Part

Number+Approvals

32mA~1:UL CSA

Note:Size of the markings have not be specified.

2.SCOPE

Used in electronic equipment.

3.OUTLINE DRAWING AND STRUCTURE

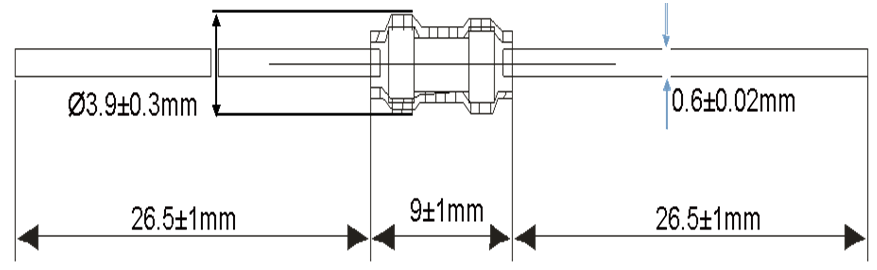

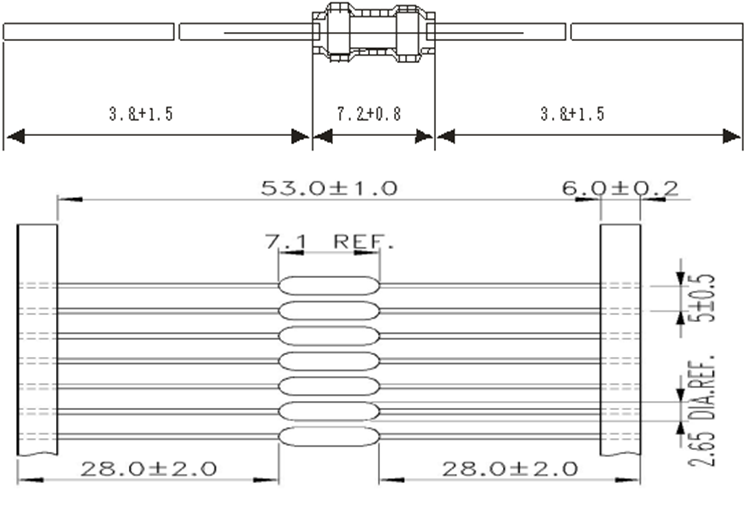

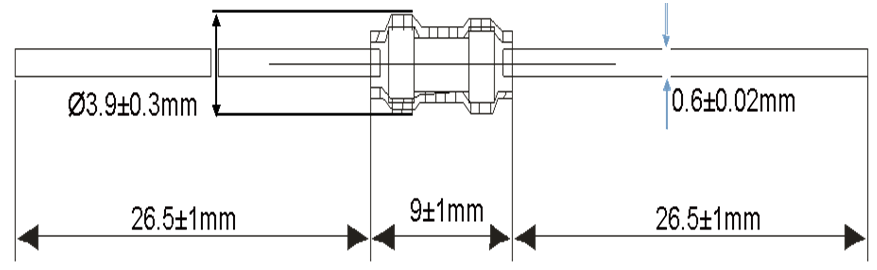

3-1 Outline Drawing and Dimensions(Unit:mm)

3-2.Structure

|

No.

|

Component

|

Material

|

Quantity

|

|

(1)

|

Wire

|

Alloy

|

1

|

|

(2)

|

Cap

|

Brass with mickel

plated

|

2

|

|

(3)

|

Body

|

Ceramic Tube/Plastic

|

1

|

|

(4)

|

Lead

|

Tinned Copper wire

|

2

|

|

(5)

|

Insulating Coat

|

Epoxy Resin

|

/

|

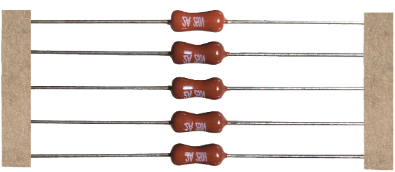

4.APPEARANCES AND CONFIGURATION

4-1Appearances:There shall not be any remaekable stain,rust

or crack on the appearances.

4-2Configuration:Axial Leaded Micro-Fuse.

5.PHYSICAL CHARACTERISTIC

5-1 Tensile test

Keep pulling the cap of the fuse with 10N at axial

direction for 1 min.

6.ELECTRICAL CHARACTERISTICS

|

% of Ampere Rating

|

Ampere Rating

|

Opening Time

|

|

100%

|

32mA - 1

|

4 Hours, Min.

|

|

200%

|

32mA - 1

|

60 Second, Max

|

|

275%

|

500mA~ 10A

|

300 msecs., Max.

|

|

400%

|

500mA~ 10A

|

30 msecs., Max.

|

|

1000%

|

500mA~ 10A

|

4 msecs., Max.

|

|

Item

|

|

Openrating Temp

|

-55ˇć~125ˇć

|

|

Test current

|

200% Rating 60SEC

|

|

Test current

|

3millisecond at 1000%

rated current

|

|

Melting I 2 t

|

1.83~2.083

|

|

Cold Ohms

|

1.2/0.058~0.067 Ohm

|

|

Interrupting rating

|

50A/125VAC

50A/250VAC

|

|

Dimensions

|

9mm*ˇé3.9mm

|

|

Ssfty

|

UL CSA CCC ROHS

|

7.ENVIRONMENTAL SPECIFICATION

7-1 Operating Temperature: -55ˇć~125ˇć

7-2 Storage Conditions

Temperature: +10ˇć~60ˇć

On average, It can be stored below the relative humidity

or 75% for 3 years.

Without dew, It can be kept under humidity of 95% for 30

days.

8.SOLDERING PAAMETERS

8-1Wave Solder

Soldering Temperature:260ˇŔ5ˇć

Soldering Time:4 Sec.Max.

8-2Manual Solder

Soldering Temperature: 350ˇŔ5ˇć

Soldering Time: 3 Sec. Max.

9.OTHER NOTICE IN USING

If heat shrink tubing was needed,the roast temperature

and time should be refer to the following.

The temperature should be sel under 150ˇć,roast time:50s

Max.

¶ţ����ˇ˘

2F-3x8 Resistor fast melt ceramic current fuse

Specification

1.MODEL NUMBER AND SAFETY

CERTIFICATION

1-1 Model Number: Part

Number+Rated Current+Rated Voltage+Approvals.

example:

2T

2A 400V

1)Part Number

2)Rated Current

1Ł© 2Ł© 3Ł©

3) Rated Voltage

1-2Rated Current And Voltage

Rated Current: 32 mA~1

Rated Voltage:125V/250V/400 AC

1-3Marking

The fuse shall have the following

marking:

Specification:Characteristic

Symbol+Rated Voltage

100mA~800mA :

_mA 1A~10A:_A

Trade mark:The

ManufactureˇŻs Logo+Part Number+Approvals

100mA~10A: TUV UL

CSA CQC

Note:Size of the markings have not be

specified.

2.SCOPE

Used in electronic equipment.

3.OUTLINE DRAWING AND STRUCTURE

3-1 Outline Drawing and Dimensions(Unit:mm)

3-2Structure

|

No.

|

Component

|

Material

|

Quantity

|

|

(1)

|

Wire

|

Alloy

|

1

|

|

(2)

|

Cap

|

Brass with mickel plated

|

2

|

|

(3)

|

Body

|

Ceramic Tube

|

1

|

|

(4)

|

Lead

|

Tinned Copper wire

|

2

|

4.APPEARANCES AND CONFIGURATION

4-1Appearances:There shall not be any

remaekable stain,rust or crack on the appearances.

4-2Configuration:Axial Leaded Micro-Fuse.

5.PHYSICAL CHARACTERISTIC

5-1 Tensile test

Keep pulling the cap of the fuse with

10N at axial direction for 1 minŁ¬and the pipe body is continuously opened

and broken.

5-2Strength of fuse tube

After the fuse pipe body is fixed, the

15N pressure is applied to the center position of the pipe body, and the pipe

body is continuously opened and broken.

6.ELECTRICAL CHARACTERISTICS

|

% of

Ampere Rating

|

Ampere

Rating

|

Opening

Time

|

|

100%

|

100mA -

10A

|

4 Hours,

Min.

|

|

200%

|

100mA -

10A

|

60 Second,

Max

|

|

275%

|

500mA~ 10A

|

300

msecs., Max.

|

|

400%

|

500mA~ 10A

|

30 msecs.,

Max.

|

|

1000%

|

500mA~ 10A

|

4 msecs.,

Max.

|

7.ENVIRONMENTAL SPECIFICATION

7-1 Operating Temperature: -55ˇć~125ˇć

7-2 Storage Conditions

Temperature: +10ˇć~60ˇć

On average, It can be stored below the

relative humidity or 75% for 3 years.

Without dew, It can be kept under

humidity of 95% for 30 days.

8.SOLDERING PAAMETERS

8-1Wave Solder

Soldering Temperature:260ˇŔ5ˇć

Soldering Time:4 Sec.Max.

8-2Manual Solder

Soldering Temperature: 350ˇŔ5ˇć

Soldering Time: 3 Sec. Max.

OTHER NOTICE IN USING

If heat shrink tubing was needed,the

roast temperature and time should be refer to the following.

The temperature should be sel under 150ˇć,roast

time:50s Max.

Čýˇ˘2.4X7Microresistor Sow-meltcurrent fuse / TUV UL CSA CQC

Specification as bellow:

1.MODEL NUMBER AND SAFETY

CERTIFICATION

1-1 Model Number: Part

Number+Rated Current+Rated Voltage+Approvals.

example:

2SMT/2T

2A 400V

1) Part

Number

2)Rated Current

1Ł© 2Ł© 3Ł© 3) Rated Voltage

1-2Rated Current And Voltage

Rated Current: 32 mA~1

Rated Voltage:125V/250V/400 AC

1-3Marking

The fuse shall have the following

marking:

Specification:Characteristic

Symbol+Rated Voltage

32mA~800mA : _mA

1A~1:_A

Trade mark:The

ManufactureˇŻs Logo+Part Number+Approvals

32mA~1: TUV UL CSA

CQC

Note:Size of the markings have not be

specified.

2.SCOPE

Used in electronic equipment.

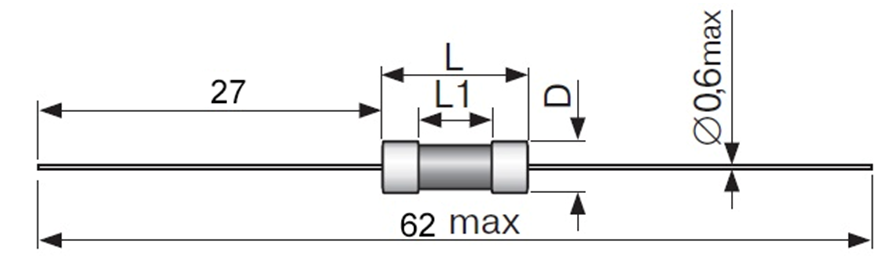

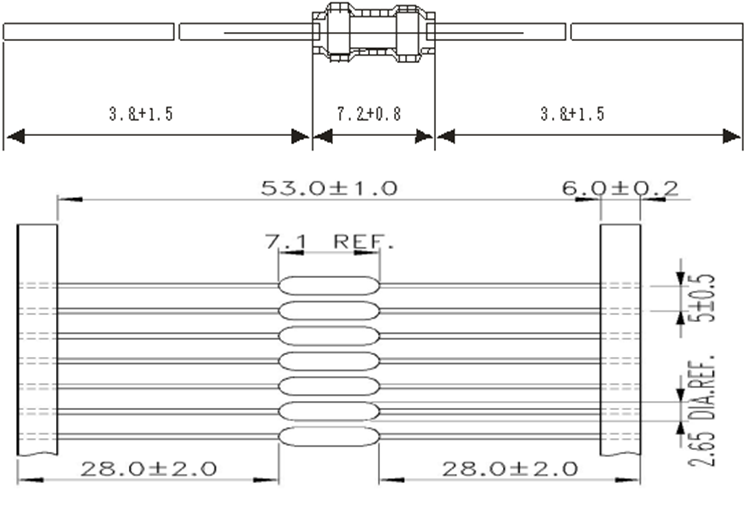

3.OUTLINE DRAWING AND STRUCTURE

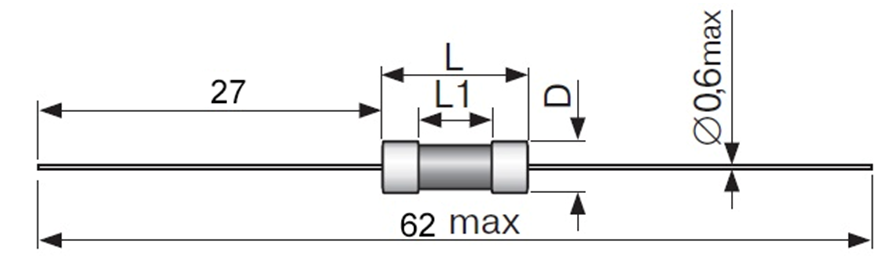

3-1 Outline Drawing and Dimensions(Unit:mm)

3-2Structure

|

No.

|

Component

|

Material

|

Quantity

|

|

(1)

|

Wire

|

Alloy

|

1

|

|

(2)

|

Cap

|

Brass with mickel plated

|

2

|

|

(3)

|

Body

|

Ceramic Tube/Plastic

|

1

|

|

(4)

|

Lead

|

Tinned Copper wire

|

2

|

4.APPEARANCES AND CONFIGURATION

4-1Appearances:There shall not be any

remaekable stain,rust or crack on the appearances.

4-2Configuration:Axial Leaded Micro-Fuse.

5.PHYSICAL CHARACTERISTIC

5-1 Tensile test

Keep pulling the cap of the fuse with

10N at axial direction for 1 min�����Ł¬and the pipe body is continuously opened

and broken.

5-2Strength of fuse tube

After the fuse pipe body is fixed, the

15N pressure is applied to the center position of the pipe body, and the pipe

body is continuously opened and broken.

6.ELECTRICAL CHARACTERISTICS

|

% of Ampere Rating

|

Ampere Rating

|

Opening Time

|

|

100%

|

32mA - 1

|

4 Hours, Min.

|

|

200%

|

32mA - 1

|

60 Second, Max

|

|

275%

|

500mA~ 10A

|

300 msecs., Max.

|

|

400%

|

500mA~ 10A

|

30 msecs., Max.

|

|

1000%

|

500mA~ 10A

|

4 msecs., Max.

|

|

Item

|

AVL1

|

2nd souece(AVL2)

|

|

TAPYE

|

Slo-Blo

|

no data

|

|

Openrating Temp

|

-55ˇć~125ˇć

|

-55ˇć~125ˇć

|

|

Temp.derating Currev

|

no data

|

no data

|

|

Test 1

|

200% Rating 60SEC

|

60sec MAX( <60Second)

|

|

Test 2

|

3millisecond at 1000% rated current

|

3millisecond at 1000% rated current

|

|

Melting I 2 t

|

3.14

|

3.14

|

|

Cold Ohms

|

1A/0.13~0.15 Ohm

|

1A/0.13~0.15 Ohm

|

|

Interrupting rating

|

50A/125VAC

50A/250VAC

|

50A/250VAC

|

|

50A/400VAC

|

|

Dimensions

|

7.2mm*ˇé2.6mm

|

7.2mm*ˇé2.6mm

|

|

Ssfty

|

UL CSA

|

CCC

|

7.ENVIRONMENTAL SPECIFICATION

7-1 Operating Temperature: -55ˇć~125ˇć

7-2Storage Conditions

Temperature: +10ˇć~60ˇć

On average, It can be stored below the

relative humidity or 75% for 3 years.

Without dew, It can be kept under

humidity of 95% for 30 days.

8.SOLDERING PAAMETERS

8-1Wave Solder

Soldering Temperature:260ˇŔ5ˇć

Soldering Time:4 Sec.Max.

8-2Manual Solder

Soldering Temperature: 350ˇŔ5ˇć

Soldering Time: 3 Sec. Max.

9.OTHER NOTICE IN USING

If heat shrink tubing was needed,the

roast temperature and time should be refer to the following.

The temperature should be sel under

150ˇć,roast time:50s Max.

|